The Story:

At the heart of the Natural Spaces Dome system is our patented connection hardware which we call the Super-Lok. Invented in 1978, the Super-Lok connection hardware was the answer to six years of dome building using inadequate wood plates, cheap metal brackets, and panelized systems.

What we were looking for was a connector that was self-aligning and so simple to put together that any dummy- sorry, that should be any “novice” dome builder could do it. We didn’t want you to have to do any of the assemblies of the strut hardware up on the scaffolding.

With our system all you do is slip the sleeve tongue into the hub slot and pound a hardened, zinc plated bolt “pin” in place, securely locking the two together. That’s it – no coming back to tighten, no re-aligning, no adjusting.

See the simplicity of our system in the video below.

In connecting the sleeve to the wood strut, anything less than four 1/2” bolts just wouldn’t do to satisfy our stringent engineering requirements. Again, the bolts and nuts are zinc plated (stainless steel nuts and bolts are an option).

The next step is just moving on to the next strut.

The sleeve (below) is made from very heavy gauge steel with an extra thick epoxy coating to make it rustproof. The coating also stops galvanic reaction with our aluminum hub.

Working with our structural engineer and our metal fabricator, we came up with our unique hub design.

The entire hub is a one piece, very high strength, aluminum extrusion.

The tongue from the sleeve fits into the slot around the perimeter of the hub. Having squashed various pipe hubs during testing, we came up with integral reinforcing spokes to strengthen the hub. It now could take extreme pressure from the struts-both pulling and pushing.

So sure were we that we had a fantastic dome connection system, we obtained a patent, #4,262,461.

The need for a super-strong connection device for domes becomes evident in examining how the dome framework reacts to loads:

The dome framework transfers all of the roof loads directly to the base of the dome. These loads get added to each other on the way down. The lower part of the dome has to be able to take 6,000 – 10,000 pounds of pressure at each lower connection point. This means that the weakest link in the ”chain” has to be able to take this pressure.

Our Super-Lok connector has been tested independently. Tests were run with our sleeve mounted on the #1-grade southern pine strut. This better resembles actual load situations.

The test tried to pull the wood strut (with our Super-Lok sleeve) from the hub. The wood split at over 15,000 pounds but did not actually come apart. Our sleeve has four 1/2″ bolts connecting it to the strut. One of our competitors uses 2 bolts in attaching a bracket to their strut. They use fir lumber which is not as strong as southern pine. Even though they use 5/8” bolts, our connection system would still hold at least 40% more stress.

For areas of the World with increased snow and wind loads along with earthquake areas, we have created our Ultra-Lok connector. This steel sleeve is larger, allowing the bolts to be spaced further apart and asymmetrically. The independent tests show the connector capacity increased 33% to over 20,000 pounds of stress.

Over the past 40+ years, we have done extensive computer engineering analysis on our dome with our structural engineers. Our system has always surpassed the structural needs of the building codes, even as they have become more stringent. Engineering done in 2014 showed that our domes will take at least 100 pounds per square foot ground snow load, along with a wind load of at least 150 mph (defined as a 3-second gust).

Earthquake loads, along with heavier snow and wind loads, can be handled using our Ultra-Lok connector. Engineering for 200 mph winds has been done for specific sites.

Our engineering also combines these loads, adding the snow, wind and earthquake loads to the dead load of our dome structure. This combination loading creates what is called ”eccentric” loading where all of the normal roof snow and wind load is put on only 1/2 of the dome. Again we surpassed the structural needs.

We think our Natural Spaces connector is the strongest dome connector on the market. Our competitors have been heard to say our system is over-engineered – we think you deserve nothing less.

Super-Lok™ Dome Connector Prices:

Prices shown below are for our patented Super-Lok Dome connection system only. This allows you to cut and fabricate all your own dome components.

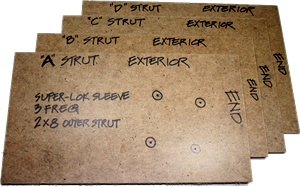

Tempered Masonite templates for positioning center punch guide holes to drill holes in struts and risers. Includes center punch, 1/2″ spade bit and riser wall hole guide template.

The NSD Dome Construction Manual includes complete installation instructions and drawings for cutting, fabricating and assembling your dome shell kit. Engineering certification of dome shell is included upon request. Plastic plan cover and two Natural Spaces Domes t-shirts included.

Our standard Super-Lok connection systems shown below include our wide Ultra-Lok sleeve for use at each riser wall corner. We require the use of 3×10 #1 Grade D.Fir KD lumber for all our riser corners. If you cannot find this 3×10 lumber in your area, we will supply these along with your connector kit. The 3×10 corner struts require a double bevel along the exterior edge, 4 holes drilled thru them to receive our Ultra-lok sleeve and a custom horizontal slot cut to receive a metal strap tie on each side of all openings for extensions. All of these custom details are provided when you purchase from us. These 3×10 corners can be shipped with your connection hardware kit. Contact us for prices which are dependent on your dome size and riser wall height.

Super-Lok™ Dome Connectors March 2025

Shown above are the components involved in a 30′ – 40′ diam. high profile dome kit with 3 openings for extensions. Click the image to enlarge. The tool package shown above comes with the purchase of the full dome shell kit (with wood components) but not with the purchase of just the metal connection hardware kit. (Current sleeve parts are coated with black epoxy.)

Shown above are all of the components in the previous photo packaged, ready for shipment or pick up.

The connector kits listed here do not include components to build our attic view cupola and skyloft floor. We are only selling the view cupola and floor as a complete pre-manufactured kit. It is a very sophisticated assemblage of very custom components (click here to see a photo of a completed kit). The complete kit can be crated and shipped via standard trucking lines (see photo). The instructions for this pre-fabricated kit system are very clear and can be erected by someone with basic building experience. Of course, our dome construction hotline is available with knowledgeable people.

Ultra-Lok™ Dome Connectors

Introduced in 2006 for our biggest domes, we are also able to increase the structural strength of our domes in areas with earthquakes, hurricanes, tornados and extremely heavy snow loads. See chart above for prices of smaller domes using the Ultra-Lok™ connector.

Paul Durand, Professional Engineer (P.E.) and Structural Engineer (S.E.), has been our consulting engineer since 1987. With his direction, we created our Ultra-Lok™ dome connection system. Our Ultra-Lok™sleeve mounted on select structural high grade 2 x 8 Southern Yellow Pine wood struts was brought to an independent testing lab, Twin City Testing. Through sophisticated machine testing, they showed that our Ultra-Lok™ connector increased the load capacity of our already strong dome system by more than 33%.

The Ultra-Lok™ system is available in all of our dome sizes for an increase in cost. If you are in an extreme wind area (straight-line winds, tornados, hurricanes), this system will greatly exceed your local codes, which are just minimum design codes.

All riser wall corners in all sizes of our domes manufactured by Natural Spaces Domes use our Ultra-Lok™ sleeve mounted on a 3×10 # 1-grade corner post. This wide Ultra-Lok sleeve is not available to purchase in the kit form unless you can obtain 3×10 #1D fir lumber. Owner builders buying our connector system will be using triple 2×10 lumber for the riser corner utilizing our Ultra-Lok sleeve, provided in the kits above.

Ultra-Lok™ Dome Connectors March 2025

The prices below include all Ultra-Lok sleeves for all the struts:

Six frequency dome kits up to 74′ in diameter are sold as complete dome shell kits only. Click here for info and prices.

To order any of the above components, call us at 651-674-4292 or email nsd@naturalspacesdomes.com.